World's Most Dynamic

Turbines Engines Hydraulic Motors Compressors Pumps

Profile

Vengeance Power Inc. is comprised of a highly talented and experienced team in partnership with private investment groups. Our extensive background in motive power R&D, product development, pioneering work in Rapid Prototyping/3D Printing, advanced 3-D CAD/CAE/CAM technology and applications provides us with skills that effectively transform any virtual concept into a viable working model which can be mass-produced.

As tinkerers from a young age, our passion for innovation in motive power drove us to develop solutions for a common problem – the idea of using pressure to spin a shaft and create torque by the most simple and efficient method. This has always been at the forefront so we perused that idea with great enthusiasm.

Operating from a lab at the University of Windsor as research engineers, helping students gain real world experience in the field of product development, we honed our skills and were able to sell a manufacturing license for our very first turbine design to a major automotive parts manufacturer. Years later, a new concept was conceived and funding through private investment allowed us to file for international patents and commence development.

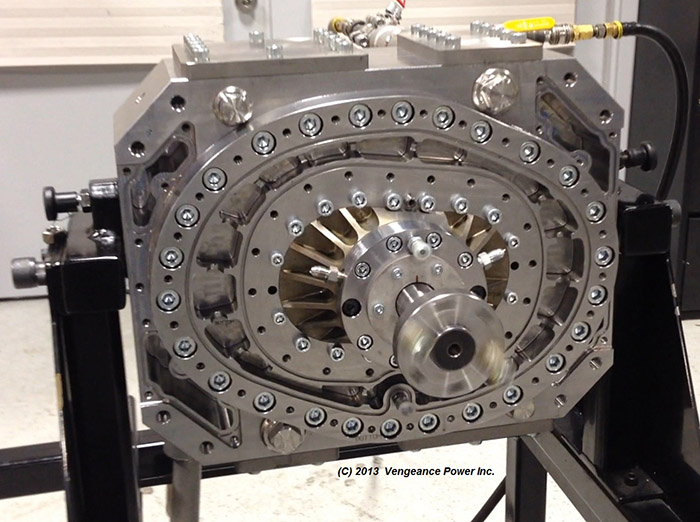

Vengeance Power Inc. was established in 2009 to develop the idea of taking a pressure from a gas/liquid and applying that force directly into rotary motion with minimal losses. After exploring many turbine designs, it was decided that the vane and rotor concept was the best candidate. This inexpensive and simple design existed for over one hundred years and is well proven. The biggest disadvantage to this design is the high friction between the vanes and rotor slots and vane tips to the casing. Internal leakage is also a problem as with other turbines. After receiving world patents addressing these issues, work was accelerated on building, testing, and distributing worldwide. We have distributed various sizes around the world for use in different applications. Through vigorous testing, developments and customer feedback for improvements, we have positioned our company to accept mass production orders with confidence in meeting deadlines as we are located in the most highly concentrated manufacturing hub in North America.

Milestones

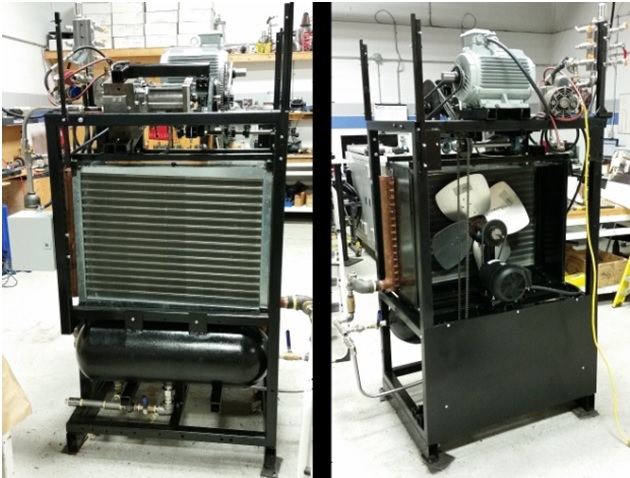

-Compressed Air Energy Storage and Power(CAESP) demonstration Expander/Genset

-New Compressor development for CAESP and other applications

-Alternative dry seal and bearing designs – demonstration models

-New product designs ready for mass-production

-Licensing options now available

-Successful demonstration of Natural Gas Pressure Letdown Expander

-New Expander Motor development for Compressed Air Energy Storage and Power (CAESP) applications

-New solutions to address CAESP thermal extremes – extreme heat and cryogenic cold

-Investigation into geothermal power, low/medium/high temperature differentials

-Very low grade waste heat recovery with special refrigerants

-Forming alliances with auxiliary equipment suppliers to offer complete systems

-New Expander development for Natural Gas Pressure Letdown applications

-Solar thermal dry/saturated/wet steam Expander application

-Investigation into new Nuclear Molten Salt Reactors, low cost steam power generation

-Opportunities for waste heat recovery of spent nuclear fuel rods – low temperature power generation

-Supercritical fluid Expander/Motor R&D

-Combined cooling & power applications – power generated from refrigerant cooling loop

-Alternative steam impulse motor development, proprietary flash steam power on demand

-New preliminary Expander designs for supercritical fluid applications

-New preliminary Compressor and Pump designs – supercooled/sub critical/supercritical

New HV-Core Series Expander development. Reduction in part count, complexity and cost. Prototype builds and testing begins. First Vengeance Organic Rankine Cycle (ORC) Expander model and system design, build and successful test.

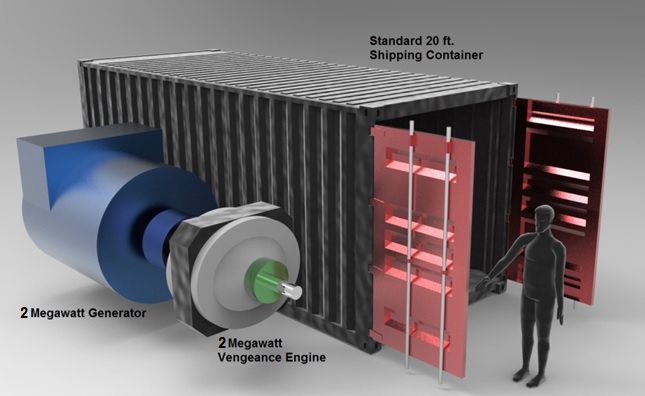

Design scale-up in output power. 100kW – 2MW build sizes possible locally. Construct design templates for large class Expanders. Modular units designed to be easily shipped anywhere.

Experimenting with new Expander configurations featuring lower part count, simpler manufacturing, lower operating and maintenance costs. Preliminary designs built and proof tested. Begin working with application-specific testing partners.

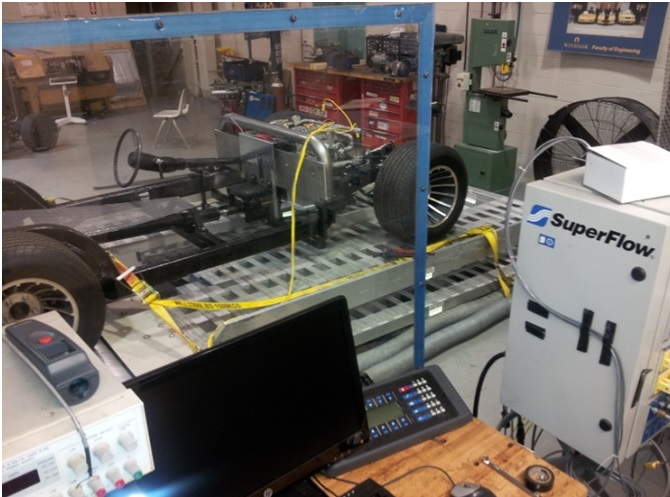

A more compact 6-Vane configuration of the Vengeance Power Expander Motor design was built and tested on compressed air as a dedicated expander which is not limited to any particular size. This was done in a real 1972 Corvette chassis and demonstrated on a chassis dynamometer providing tremendous torque at low speeds and pressures. This enables the use of any pressurized fluid to drive the Vengeance Power Expander including air (CAES), steam, ORC fluids, external combustion (Brayton cycle), supercritical fluids and pulse detonation. When running on steam, condensation occurring within the Expander as the fluid expands and cools had no negative effect. In fact, our Expander doubles as a formidable Hydraulic Motor providing incredibly high smooth rotary torque with no pistons. It can also run in reverse as a compressor or pump.

Working with our academic community to advance research and development, we give students the opportunity to work with the latest industrial technologies while also supporting our local economy.

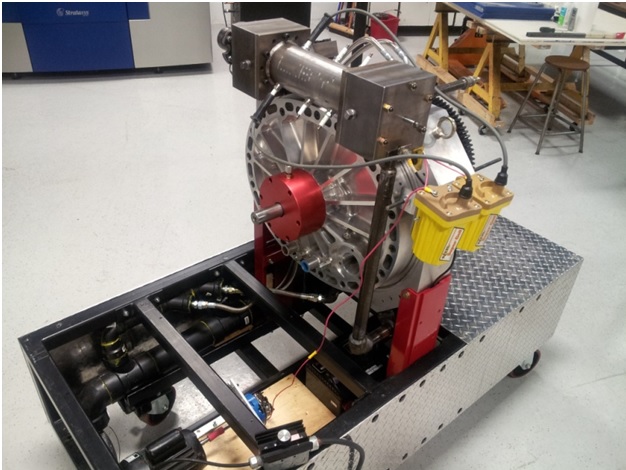

The Vengeance Power Engine successfully ran on the Brayton Cycle. Our proprietary External Combustion / Pulse Detonation Wave device was mounted on the engine and various fuels including gasoline were combusted to provide the force to spin the output shaft. The addition of the Brayton Cycle makes it possible to raise the efficiency by combining the Rankine Cycle which allows the engine to run on both cycles simultaneously. The Brayton Cycle in conventional turbines requires high velocities since they do not have sealed expansion chambers. Because the Vengeance Power Engine has sealed expansion chambers, the speed required to do work is much lower. This makes it a true positive displacement sealed turbine engine.

Vengeance Power Inc. was recently awarded the Professional Engineers of Ontario (PEO) award for the Innovation Challenge Competition in September, 2012.

Successful first test of our prototype Hybrid Radial Impulse Steam Turbine featuring low rpm, high torque, low cost, simple manufacturing and maintenance.

In December 2012, Vengeance Power Inc. was chosen by a world military supplier to begin discussions on implementation for waste heat recovery applications in battlefield / tactical applications.

The engine ran successfully on external combustion using steam proving out the Rankine Cycle. This demonstrated the engine’s ability to run on waste fuels and as a waste heat engine. A torque output test also proved the tremendous torque output predicted in the CAD model. These tests also demonstrated the engine as a viable Organic Rankine Cycle engine using refrigerant vapor pressure from low-grade waste heat sources. Compressed air tests demonstrated the wide range of applications including CAESP (Compressed Air Energy Storage & Power) systems.

Successful internal combustion firing tests proved out the Otto Cycle concept where all four strokes of Intake, Compression, Power and Exhaust were demonstrated.

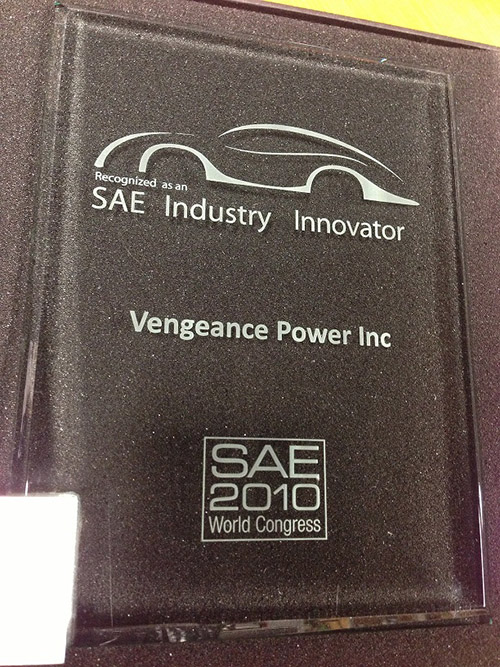

Vengeance Power Inc. was recognized as a Society of Automotive Engineers (SAE) Industry Innovator at the 2010 SAE World Congress in Detroit, Michigan.