World's Most Dynamic

Turbines Engines Hydraulic Motors Compressors Pumps

Expander Turbines

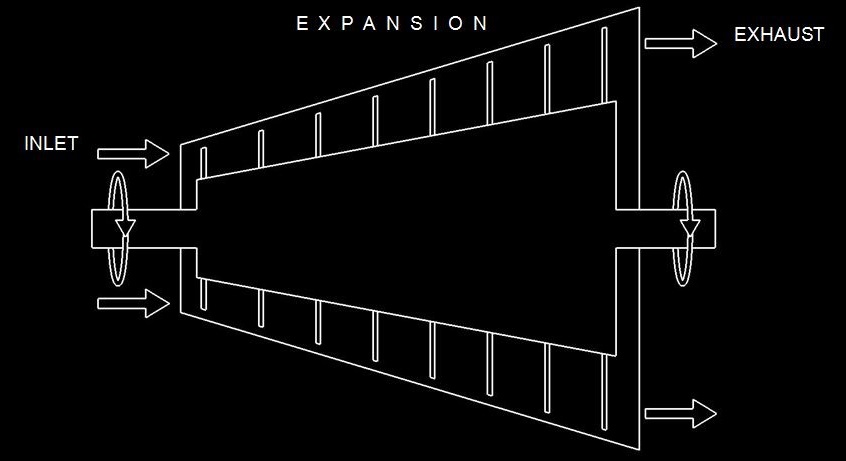

Traditional Multistage Expander Turbines – Drawbacks

Conventional expander turbines need to operate at very high speeds and require multiple expansion stages to reach high power and efficiency. As the gas expands, the pressure drops requiring more sets of larger and larger blades. This leads to the familiar cone shape and drastically increases the complexity, cost, size, weight and part count.

The Vengeance Turbine Solution

Multistage Expansion in a Single Stage Unit

Here, you can see the obvious benefits:

- simplicity

- fewer parts

- smaller size

- very long expansion strokes

- higher torque at lower speeds

- does not require oil lubrication

- unlimited expansion ratio capability

- lower operating and maintenance costs

- lower manufacturing, materials, assembly and distribution costs

- on demand throttling ability -not an option with conventional turbines

- more expansion into the “wet vapor zone” which destroys conventional turbines

- more exposed Vane surface area providing maximum force and torque as the pressure drops

- cooler exhaust and faster condensation, putting less strain on closed-loop condenser arrays

- smaller and cheaper condenser arrays for closed-loop Rankine (steam) cycles or ORCs