Our Products

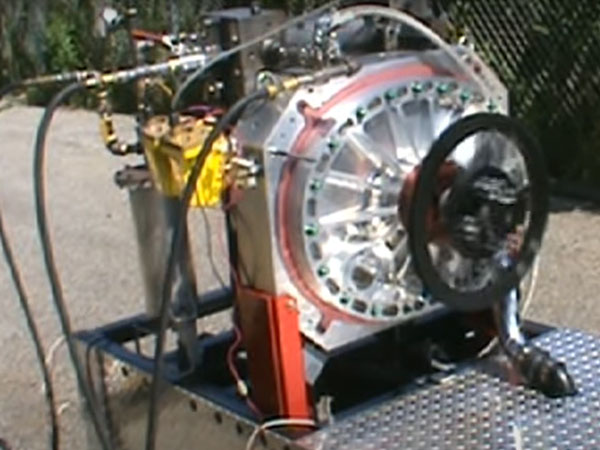

Order with or without our Generator kits

Various working fluids and cycles:

·Superheated Steam, Saturated/Wet Steam, Supercritical Fluids

·Organic Rankine Cycle (ORC) with natural and synthetic refrigerants (Including Ammonia, Binary and Supercritical CO2)

·Kalina Cycle

·Stirling Cycle

·Compressed Air, Nitrogen

·Natural Gas Pressure Letdown

Learn more

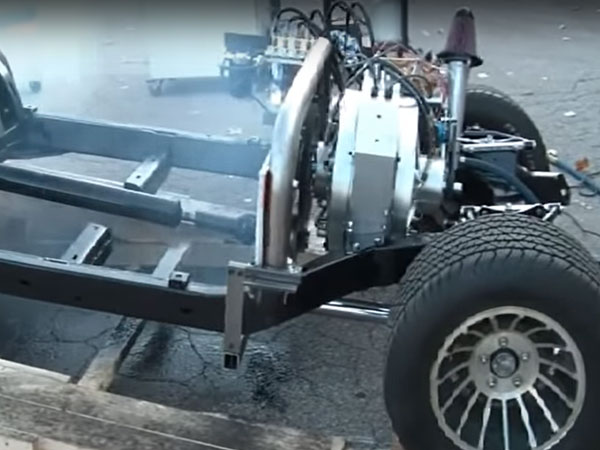

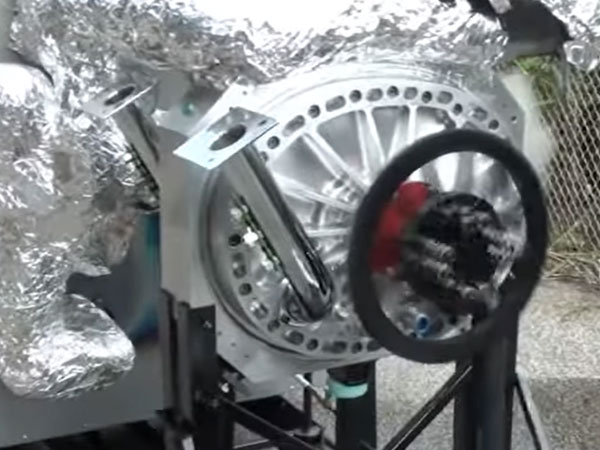

Internal Combustion (2, 4, 5 Stroke), Compression Ignition

External Combustion, Brayton Cycle, Stirling Cycle, Pulse Detonation Wave

Fuels: Gasoline, Diesel, Biodiesel, Natural Gas, Propane, Ethanol, Dimethyl Ether

Zero Carbon fuels : Ammonia, Hydrogen, Oxy-Hydrogen, Hydrazine, Hydrogen Peroxide*

Learn more

*NEW*

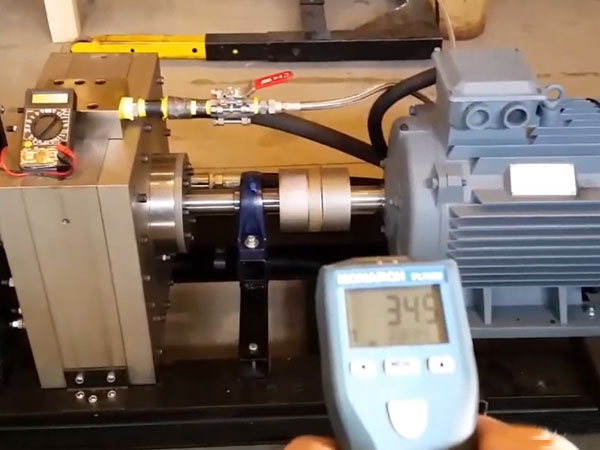

The unique torque multiplying effect of our turbine engines also applies to our hydraulic motors, providing extremely high torque and direct shaft power at very low speeds. No gearboxes required!

Our hydraulic motor units offer robust performance with competitive pricing and reliability compared to traditional motors.

Learn more

*NEW*

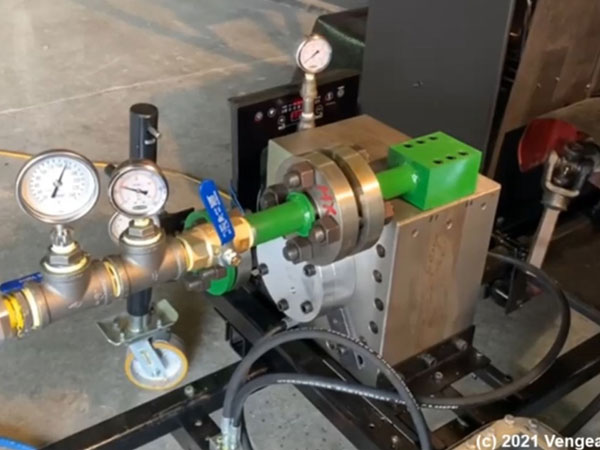

We reconfigured our turbine engine as a back-torque reducing compressor with distinct advantages over traditional compressors. Less input power is needed to generate high output pressures without a gearbox. Our design flexibility allows for various compression ratios. New patents issued & pending.

Learn more*NEW*

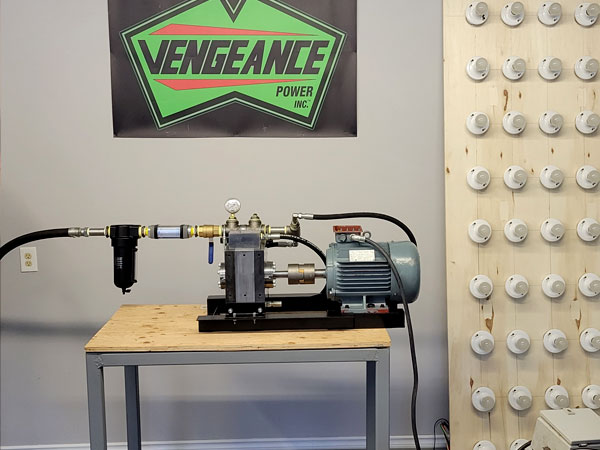

As with our fully customizable Compressor designs, our new Pump designs feature very high volumetric flow rates in a compact design with lower speeds, increasing efficiency. The wide open port valveless design minimizes flow restrictions, preventing turbulence and fluid cavitation at the inlet.

Learn more